Have you ever seen a freshly poured concrete floor slab and wondered how precise the shape and smoothness are? Slab formwork systems – an indispensable building component – hold the key to efficient and meticulous concrete construction. The shuttering system helps to shape and support the concrete while it is being poured, aiding in faster curing, a greater finish and overall efficiency.

Let’s understand how modular formworks for slabs and beams are transforming the modern construction industry.

The primary advantage of using modular formworks is it helps speed up the construction process. The formworks comprise prefabricated components and panels that are quicker to install and do not require professionally trained labourers. No drilling is required – the forms feature unique clasp and lock systems to ensure effortless installation.

Additionally, modular concrete shuttering eliminates the need to build forms on-site, so they get assembled in just a few hours. Hence, the construction work is completed more efficiently and faster.

Using a plastic formwork system gives you the flexibility to achieve any desired shape, dimension and finish. you can easily achieve accurate dimensions, alignments and finish using slab formworks.

Thanks to their fantastic flexibility and usefulness, you can custom-design slab forms to suit any type of architectural specification or design. Regardless of the design, the formwork system can be tailor-made to achieve any size, shape or load-bearing capacity. Additionally, you can use them for multiple construction projects as dismantling is as simple as installation.

The well-designed and sturdy concrete shuttering forms the foundation of a safe and stable construction site. It can efficiently handle wet concrete, minimising the risks of collapse and improving the safety of the workers during the concrete pouring process. In fact, the number of accidents has reduced over time owing to formwork construction. Earlier, the assembling of parts and dismantlement were accident-prone. However, the risk has significantly gone down with the use of slab forms.

As discussed earlier, using modern formworks for slabs and beams significantly reduces the need for professionally trained labourers. They further aid in quicker or more precise construction. Greater efficiency enables you to minimise waste and save more on your costs.

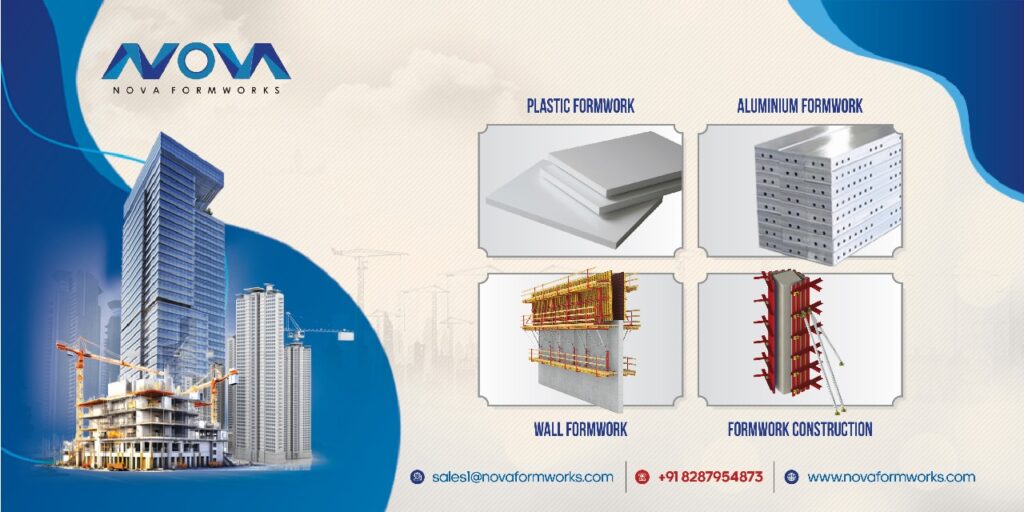

By integrating slab forms in construction projects effectively, you can benefit from greater quality, enhanced efficiency and a safe work environment. When it comes to using premium-grade slab formwork systems, Nova Formworks is one of the leading brands you can trust. They specialise in manufacturing plastic and aluminium formwork systems that ensure a longer lifespan, greater versatility and easier installation. These shuttering systems can go a long way in improving the efficiency of your construction project and minimising costs.

WhatsApp us