Formwork Consulting

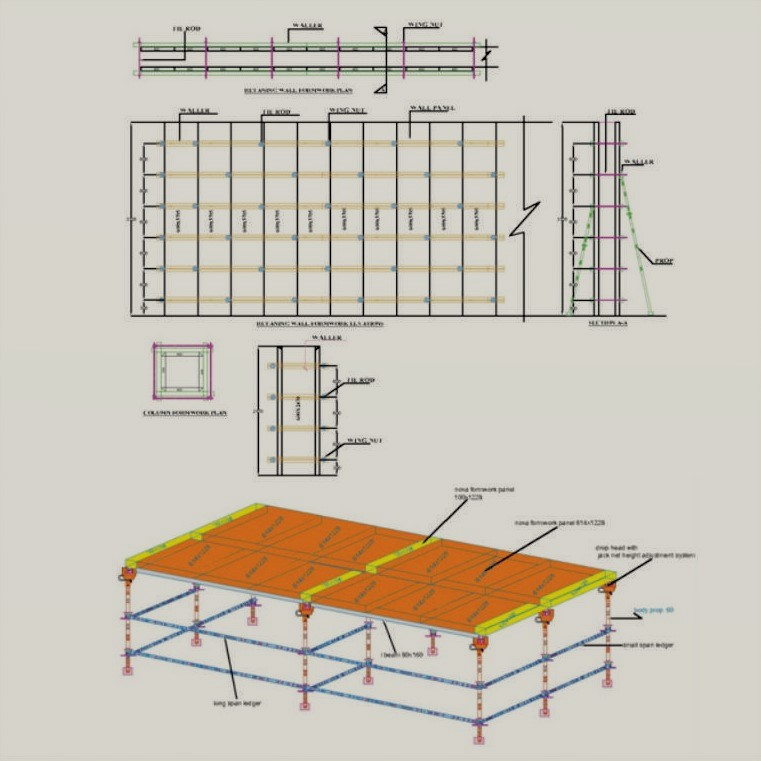

Apart from manufacturing of plastic formwork, Nova Formworks has earned a market reputation as a provider of technical assistance in the construction sector. The company has a defined consulting process wherein we study the blueprint of the project and analyze the total formwork requirement in vertical and horizontal aspects. Our technical experts evaluate the sizes of the panels needed to make the right sizes of columns and walls tomaximise the number of repetitions of panels and hence reduce the overall cost of the project.

Our team also works out all the related accessories required. Consequently, we discuss with the construction personnel about the type of system they would like to adopt for construction: a stage-by-stage process or a monolithic construction module. Post which, our team recommends the formwork as per the requirements.

During the entire implementation of the project, our technical team and engineers handhold the client in terms of guidance and assistance. Our engineers are present on-site to assist at the installation stage and provide training on-site as well.

The Research &Development team at Nova Formworks is committed to assisting its clients across all stages of the project from conceptualization to actual installation of formwork systems. With the dedication and commitment our teams showcase while assisting our clients has helped our company earn immense respect in the market.

Case Study- One of our clients was using steel plates for casting drain walls. He wanted to cast 100m per day to finish his project on time. But due to the weight of steel plates, he only got cycle time of 3 days as the labour took a lot of time in transporting the plates. He also got very bad finish as steel started getting corroded as well because of the environment, and hence had to invest a lot in plastering the walls as well. After consulting with us, he shifted to our product.Because our product is much more lightweight when compared to steel plates, he got cycle time of 24hrs!The labourwere also very happy, because it was very easy to use and lightweight, there was no corrosion and excellent finish. He used the panels on more projects afterwards and is a client to this day!

Case Study 2- Another client wanted a trolley constructed for casting drain walls, so that he could get better cycle time. We helped him with the design of the drain trolley, manufacturing it in-house and implementing the trolley on site.