NOVA PLASTIC FORMWORK

Established in 2004, Wonder Moldplast Pvt. Ltd., is one of the most recognized names as a manufacturer, trader, and exporter of Plastic Products. To increase its reach and visibility, the company has ventured into manufacturing of quality plastic formwork systems in India under the brand Nova Formworks. Largely used in construction, our products comprises of panels that can be easily locked with the use of pins and wedges. The system is modular and can be used in the construction of all kinds of walls, verticals, box culverts,slabs,beams etc. The company is also into the customization of the products to meet the requirement of the customers. The products at Nova Formworks are broadly divided into three categories: Nova Plasform, Nova Alplas and Nova Aluform and is equipped to provide all kinds of formwork solutions in the market.

NOVA PLASTIC FORMWORK is one of our most popular products of Nova Formworks. It is an advanced plastic formwork with GI supported stiffner that are attached to the back of the panels. Best suited for all vertical and horizontal applications, these panels are strong and robust making it nearly unbreakable apart from being lightweight (15-18 kg/sq.mt). The same panels can be used in all applications like wall, slab, box culvert, columns, drains, and other concrete applications making it a multipurpose product. The panels are locked with a unique locking system with each other using plastic pins and wedges. The vertical lateral pressure of 6 tons/sqmtr is the minimum load-taking capacity.

Nova Plastic Formwork System Benefits

Nova plastic form-work system can be stacked on each other, reducing the space required to store. Besides, this formwork can be kept outside, indoor, in basements where there is water logging as it has no effect of water. Moreover, it is UV resistant.

There is no need to drill holes into the formwork. Plastic caps and plugs can be inserted into the remaining tie-rod holes opening. This ensures clean concrete surfaces and longer life of the formwork. Moreover, it saves time to drill and close the holes.

Concrete does not stick to the plastic material of our products. This reduces labour costs and saves time and energy. Even the use of shuttering oil can be reduced to a very large extent and hence its cost. It can be cleaned after every use with water.

Nova Formwork Panel has a unique locking system of pin and wedges that is easy to use. Moreover, it is very lightweight. Since it is easy to use, even unskilled labour can fix it, so it saves on labour cost too.

Saves time and labour.

Nova Plastic Formwork system has a very low surface tension, so it does not stick to concrete making it very easy to remove and reuse without any major cleaning work, unlike steel. As a result, it saves time and labour.

There is no need to plaster you can apply putty and paint directly. This is a huge saving on plastering cost, thereby making formwork economically viable.

It can be reused more than 100 times very easily. With proper handling, people have used it for more than 200 times as well. Hence, it saves money.

After using it for many years, it will still fetch a good scrap value which plywood formwork cannot give. Thus, it reduces total cost.

As it is a 100 % recyclable green product compared to any other formwork system it can generate carbon credit.

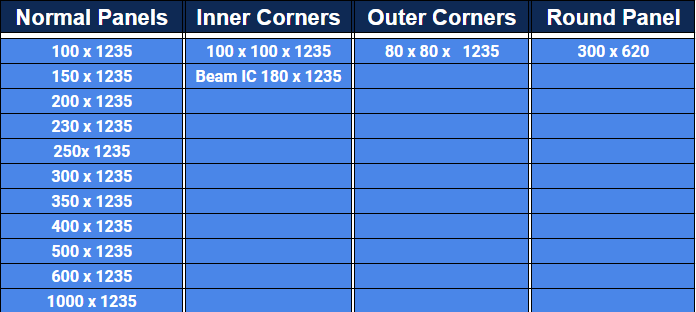

Panel Sizes