And yet, no one questioned it. Until we did.

From Plastics to Purpose

Backed by over 40 years of experience in plastic innovation, our founders knew the material inside out — its strength, its adaptability, and its potential to solve real-world problems.

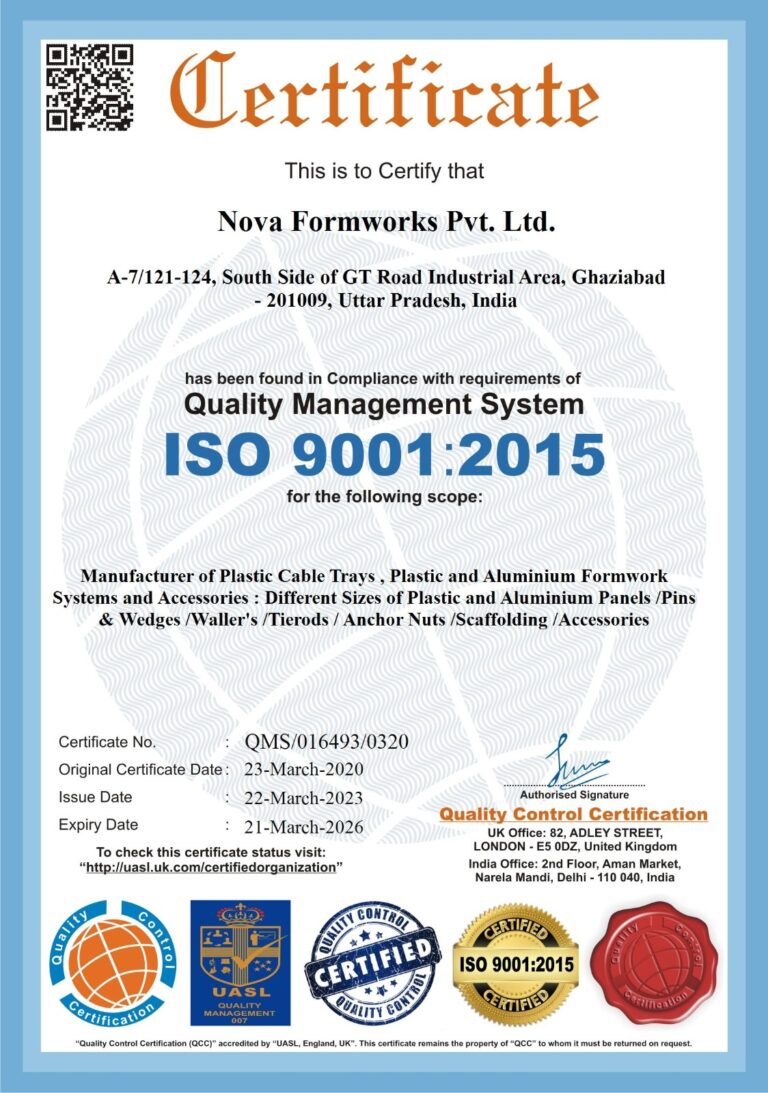

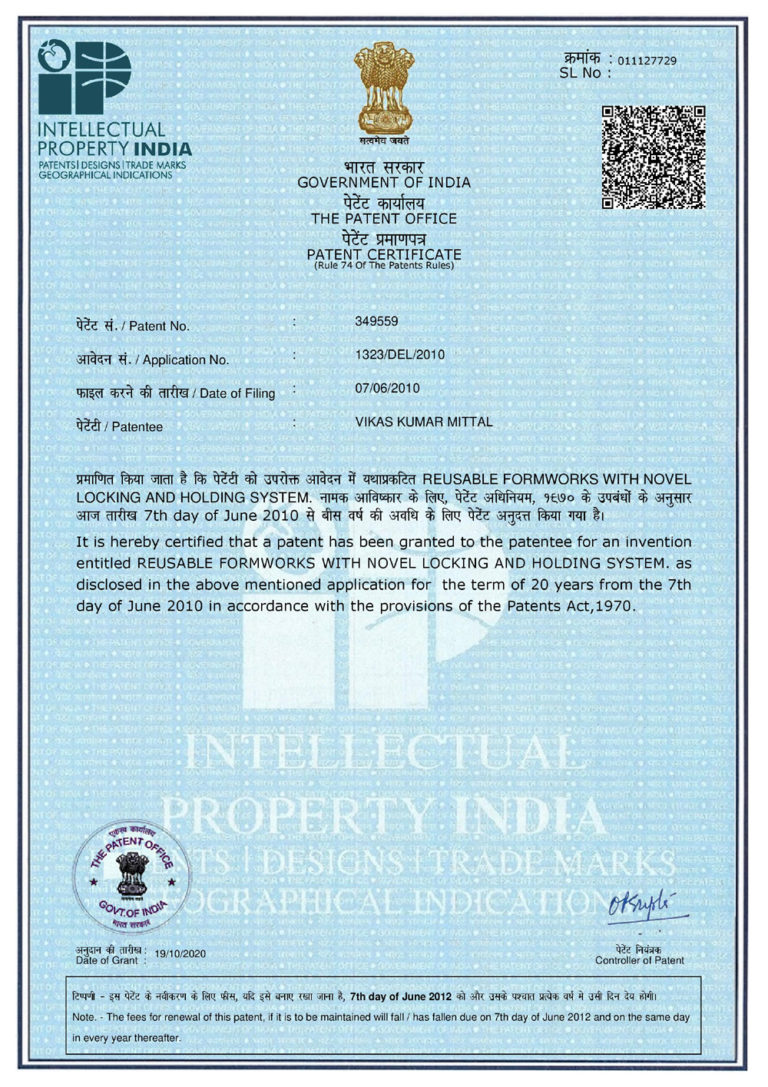

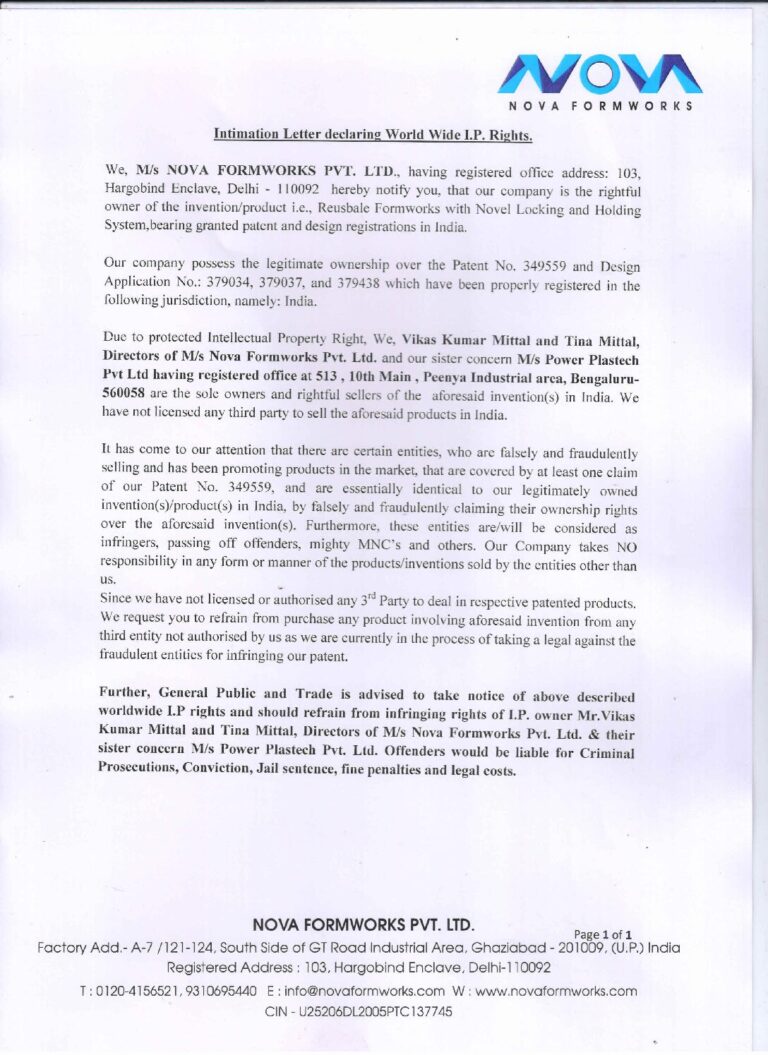

In 2011, we turned that experience toward construction and created something the industry hadn’t seen before: Nova Formworks — our patented, reusable, modular plastic formwork system that is lightweight, durable, easy to handle, and built to perform again and again, without compromising on the finish.

No nails. No oiling. No waste. Just a smarter way to shape concrete — and a better way to build.

Changing How the Industry Builds, One Project at a Time

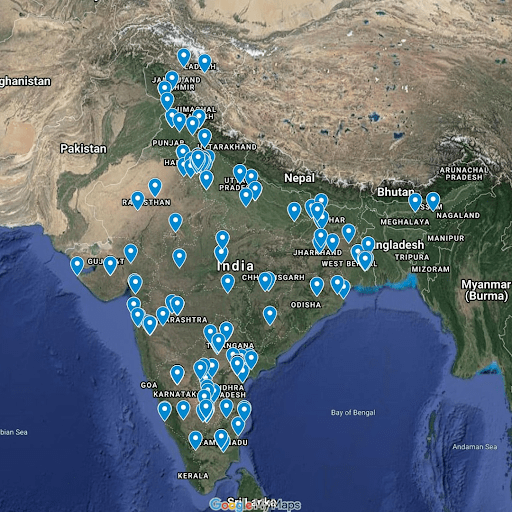

Since then, Nova Formworks has been trusted on thousands of sites across India and internationally — from affordable housing and commercial developments to complex infrastructure projects. But we don’t measure our success in square feet or sales.

We measure it in the relief of a worker lifting a lighter panel. In the calm of a project manager finishing ahead of schedule. In the quiet pride of building with less waste, and more care.

We’re Not Done Building Better

Nova was never just about creating a product. It was — and still is — about making construction more humane, more sustainable, and more intelligent. We keep listening. We keep improving. Because the future deserves better tools — and the people building it deserve better support.

Let’s talk. Whether you’re planning your next project or rethinking how your team works, we’re here to help you build better — from the ground up.

A promise of excellence — by redefining how the world builds, with smarter systems and sustainable impact.

To drive construction forward with innovation-led solutions that are practical, scalable, and built for a better tomorrow.

Rooted in trust, powered by integrity, and guided by people — we deliver quality and innovation that stand the test of time.

Nova formwork has many advantages over the conventional formwork available :

The demand for the quantity of materials on-site is minimized, as the identical panels can serve multiple purposes such as walls, slabs, shear walls, columns, foundations, pile caps, rafts, and more.

Repetitions/Usability : 8-10 Times

Surface finish : Average Good

Storage : Warehouse Required

Eco friendly : No

Corrosion : No

Water Resistance : No

Installation Striping : Difficult

Weight : Moderate

Chance of Theft : Low

Shuttering Oil : Yes

Load/ SqMetre : 4 Tons

Recyclable : No

Resale Value : No

Maintenance : N/A

Cost : Low

Requirement of Skilled labor : High

Repetitions/Usability : 30-35 Times

Surface finish : Average Good

Storage : Warehouse Required

Eco friendly : No

Corrosion : Yes

Water Resistance : No

Installation Striping : Moderate

Weight : Heavy

Chance of Theft : High

Shuttering Oil : Yes

Load/ SqMetre : 4 Tons

Recyclable : Yes

Resale Value : Yes

Maintenance : High

Cost : Moderate

Requirement of Skilled labor : High

Repetitions/Usability : 80-100 Times

Surface finish : Excellent

Storage : Warehouse Required

Eco friendly : No

Corrosion : No

Water Resistance : No

Installation Striping : Easy

Weight : Moderate

Chance of Theft : High

Shuttering Oil : Yes

Load/ SqMetre : 4 Tons

Recyclable : Yes

Resale Value : Yes

Maintenance : Average

Cost : Expensive

Requirement of Skilled labor : Low

Repetitions/Usability : 100+ Times

Surface finish : Excellent

Storage : No Special Place Required

Eco friendly : Yes

Corrosion : No

Water Resistance : Yes

Installation Striping : Easy

Weight : Light Weight

Chance of Theft : Low

Shuttering Oil : No

Load/ SqMetre : 5.5-6 Tons

Recyclable : Yes

Resale Value : Yes

Maintenance : Low

Cost : Economical

Requirement of Skilled labor : Low

Founder, Nova Formworks Pvt. Ltd.

Some stories begin with bold ideas. This one began with a simple question:

“Can we build better — for people, for projects, and for the planet?”

For Vikas Kumar Mittal, building was always part of life. Raised in Bengaluru, he grew up in a household where plastics weren’t just materials — they were part of dinner table conversations, business decisions, and family dreams. His father had set up a manufacturing business in 1976, and from an early age, Vikas saw the effort it took to create something meaningful from the ground up.

After completing his education, he stepped into the business not as a boss, but as a learner. Starting from the shop floor, Vikas quickly earned his stripes managing the factory, learning how every machine moved, every decision mattered, and every product could make someone’s life easier.

He had a sharp eye for what people needed — and where things could be better. In 1999, he helped the family expand into plastic molded furniture, bringing practical and well-designed products to homes and workplaces across India.

Not long after, he relocated to Delhi to set up a manufacturing unit that would serve the northern region. It was a new market, a new challenge — and one he took on wholeheartedly. But it wasn’t just about manufacturing. Vikas had a vision: he wanted to build products that didn’t just work — they made a difference.

Around 2005, when India’s construction industry was booming, Vikas noticed something. Despite the progress, the tools used on sites hadn’t caught up. Plywood formwork systems were slow, wasteful, and labor-intensive. He saw how much effort went into making them work — and how much time and money they cost in the long run. He believed there had to be a better way.

With years of experience in plastic engineering, Vikas started exploring the idea of a modular plastic formwork system — one that could be reused, reduce labor demands, improve finish quality, and help projects move faster. There were failed attempts, setbacks, and learning curves. But in 2011, that belief turned into reality— Nova Formworks was born.

What started as an experiment quickly became a movement. Nova’s patented plastic formwork system changed how construction teams worked — offering speed, precision, durability, and sustainability all in one. Over time, it became a trusted partner on thousands of job sites across India and abroad. But if you ask Vikas what he’s proudest of, it’s not just the product. It’s the people. It’s the engineers who innovate alongside him. The clients who trust Nova with their biggest projects. The teams who show up every day to build something better. And the impact Nova is creating — not just in buildings, but in livelihoods, communities, and the environment.

Today, Vikas continues to lead with the same spirit that brought him here — one of curiosity, integrity, and care. He is also deeply committed to giving back, actively supporting Round Table India, helping build schools and opportunities for children who deserve every chance to thrive.

His goal is simple:

To take Nova’s mission across India and beyond — making sure no builder ever has to choose between quality, efficiency, or sustainability.

WhatsApp us